|

INSPECTION

PONDY SG CERTIFIED WITH THE FOLLOWING MANAGEMENT SYSTEMS:

- Pressure Equipment Directive 2014/68/EU

- Material Manufacturer acc. to AD 2000-Merkblatt W 0

- ISO 45001 : 2018 - Management System

- ISO 14001 : 2015 - Management System

- ISO 9001 : 2015 - Management System

|

|

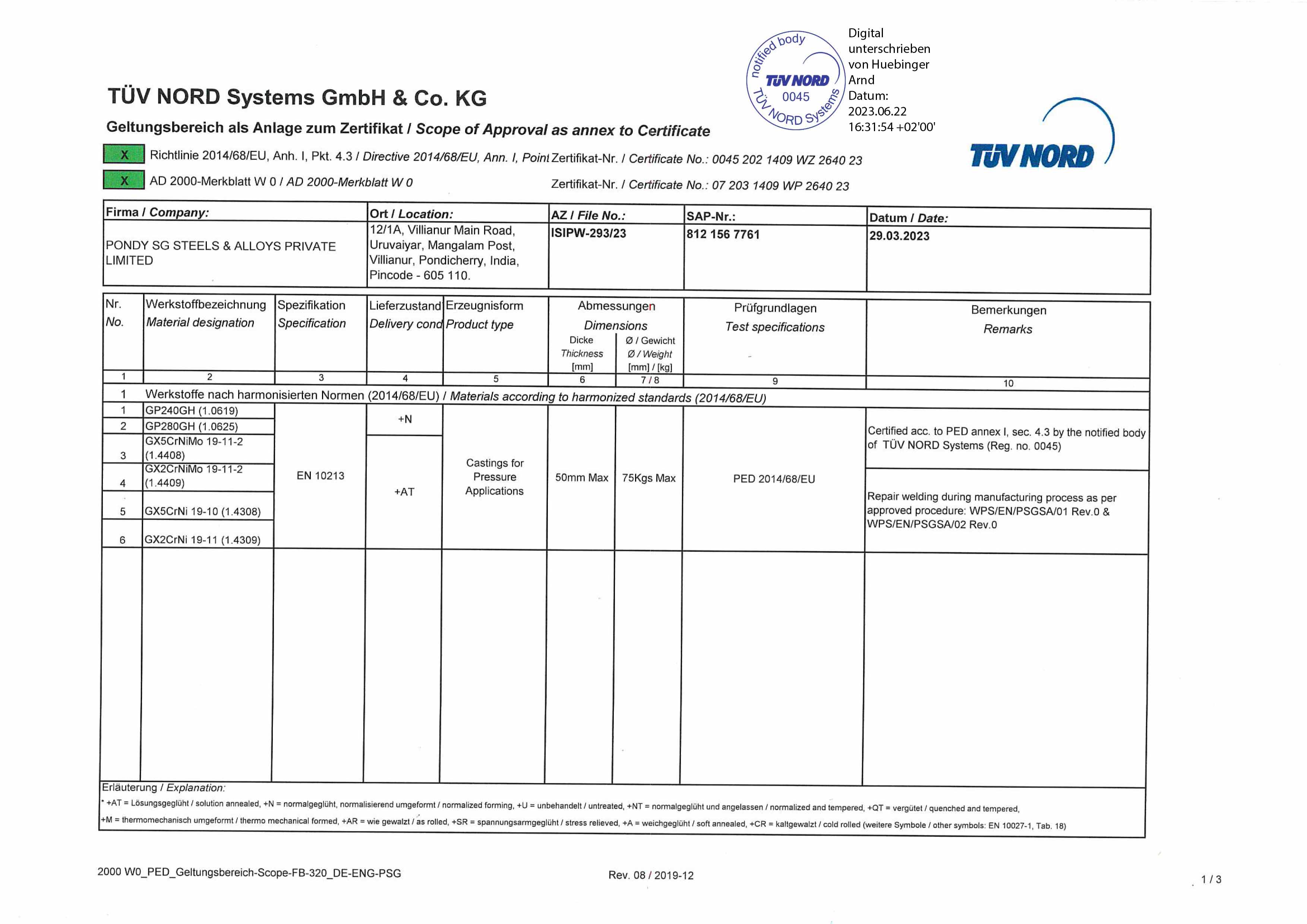

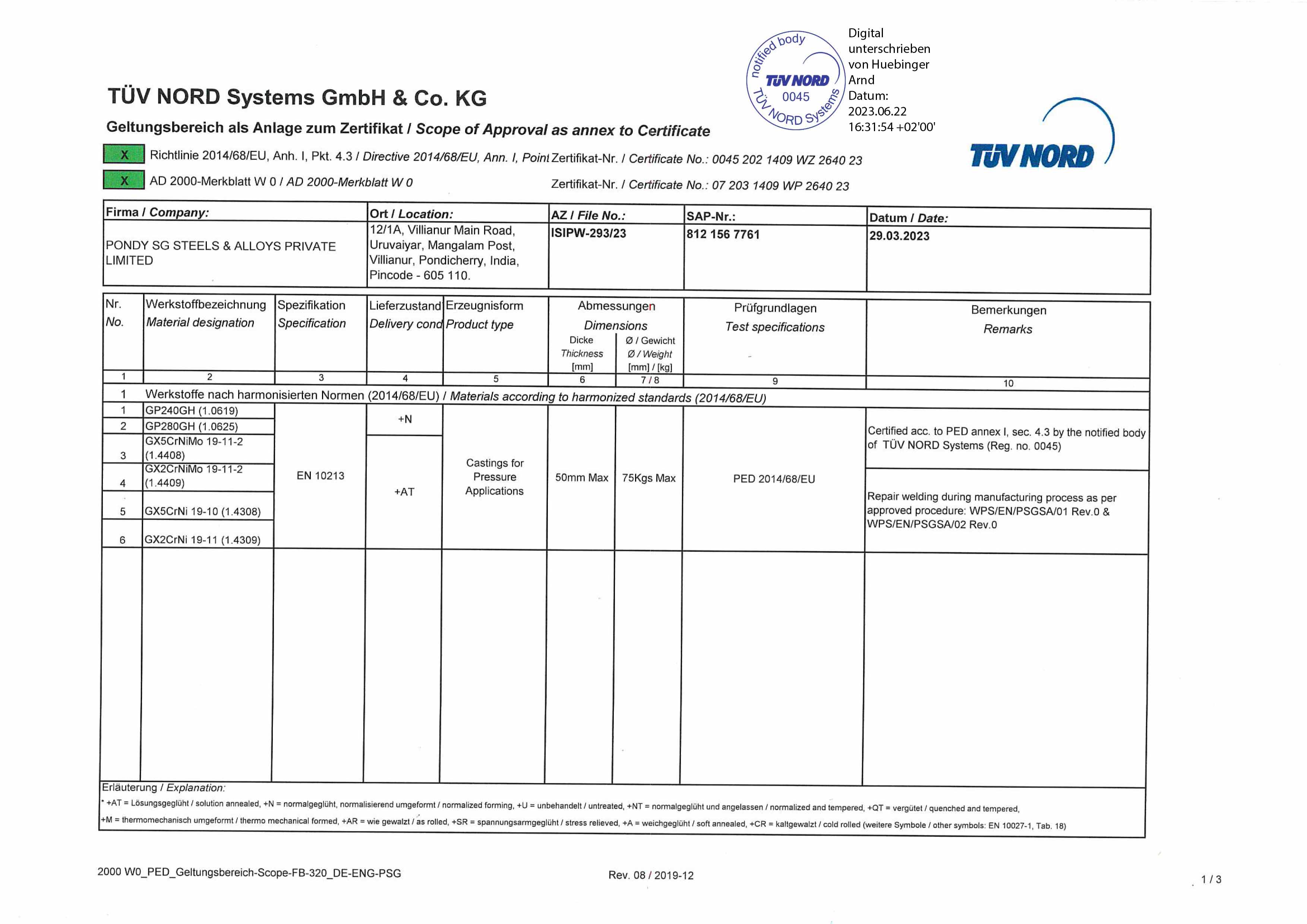

Pressure Equipment Directive 2014/68/EU (Page 1)

|

|

|

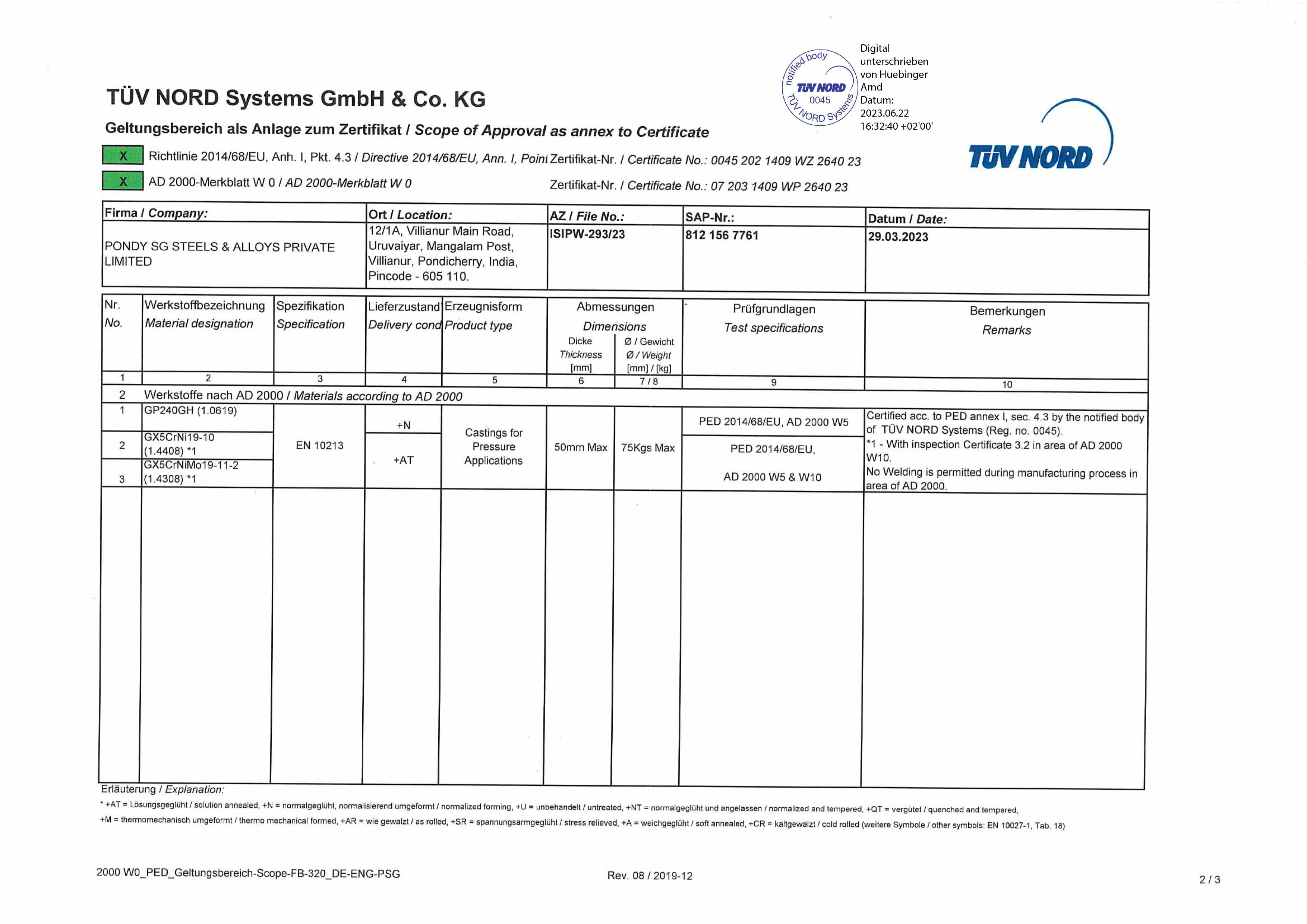

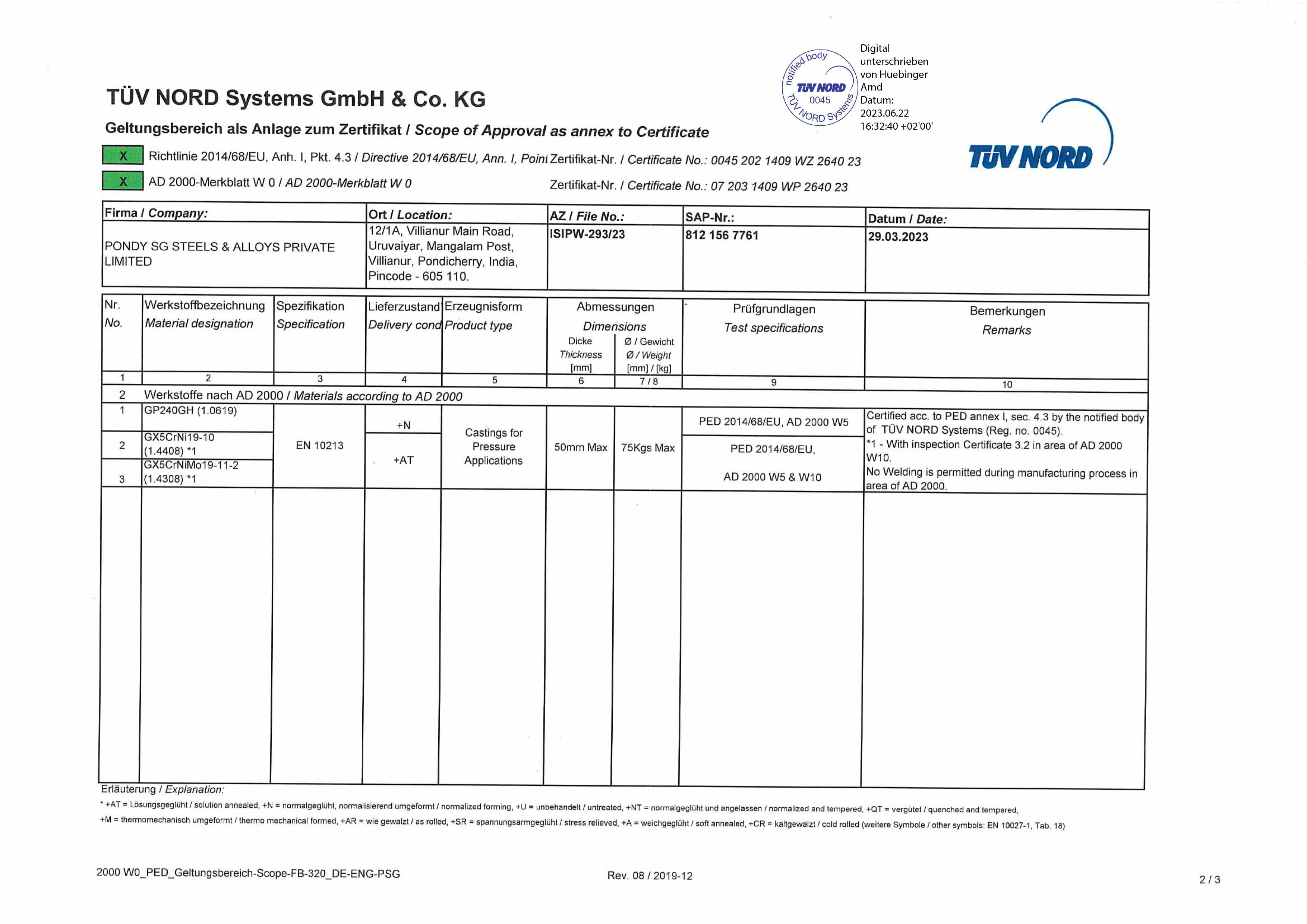

Pressure Equipment Directive 2014/68/EU (Page 2)

|

|

|

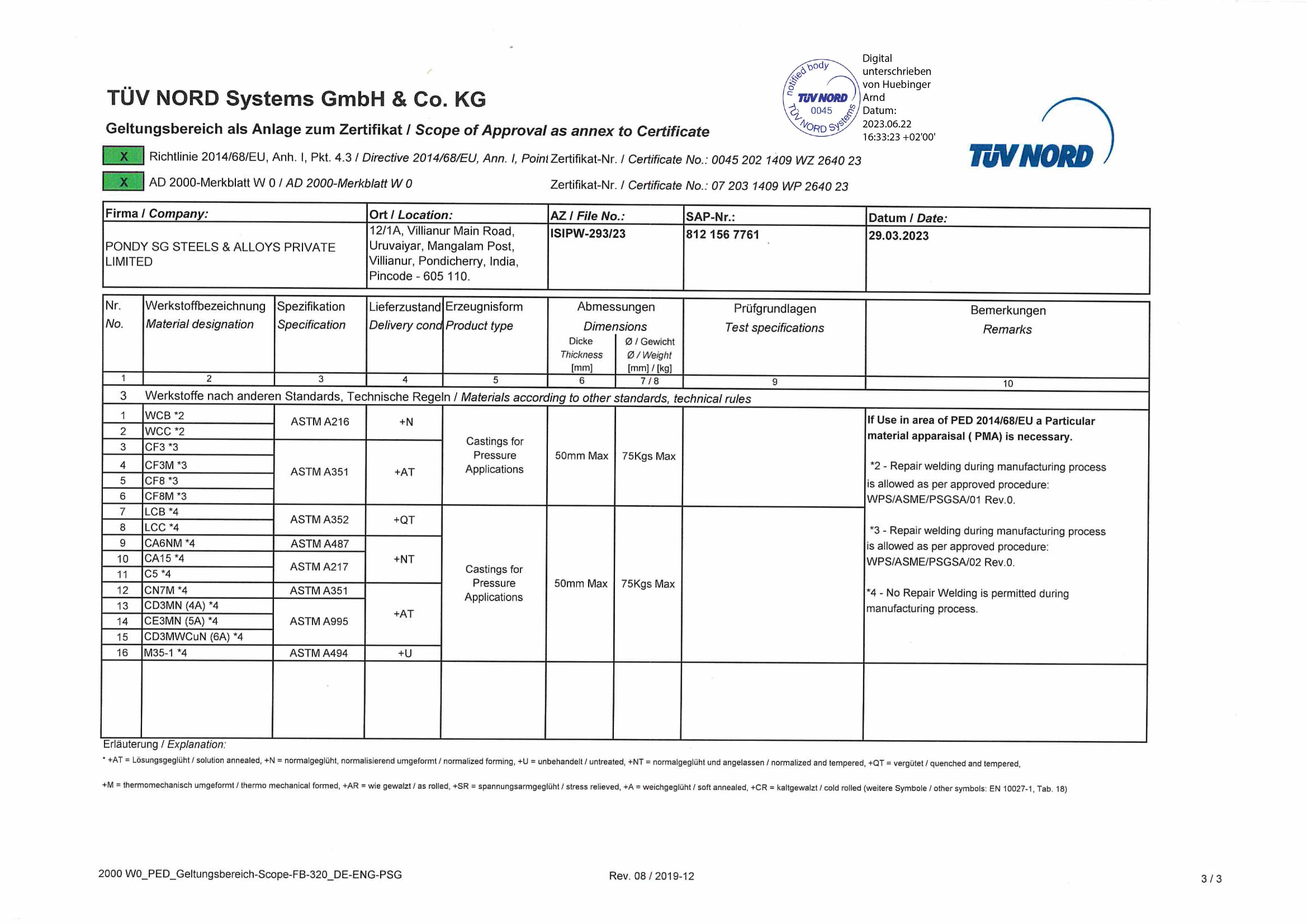

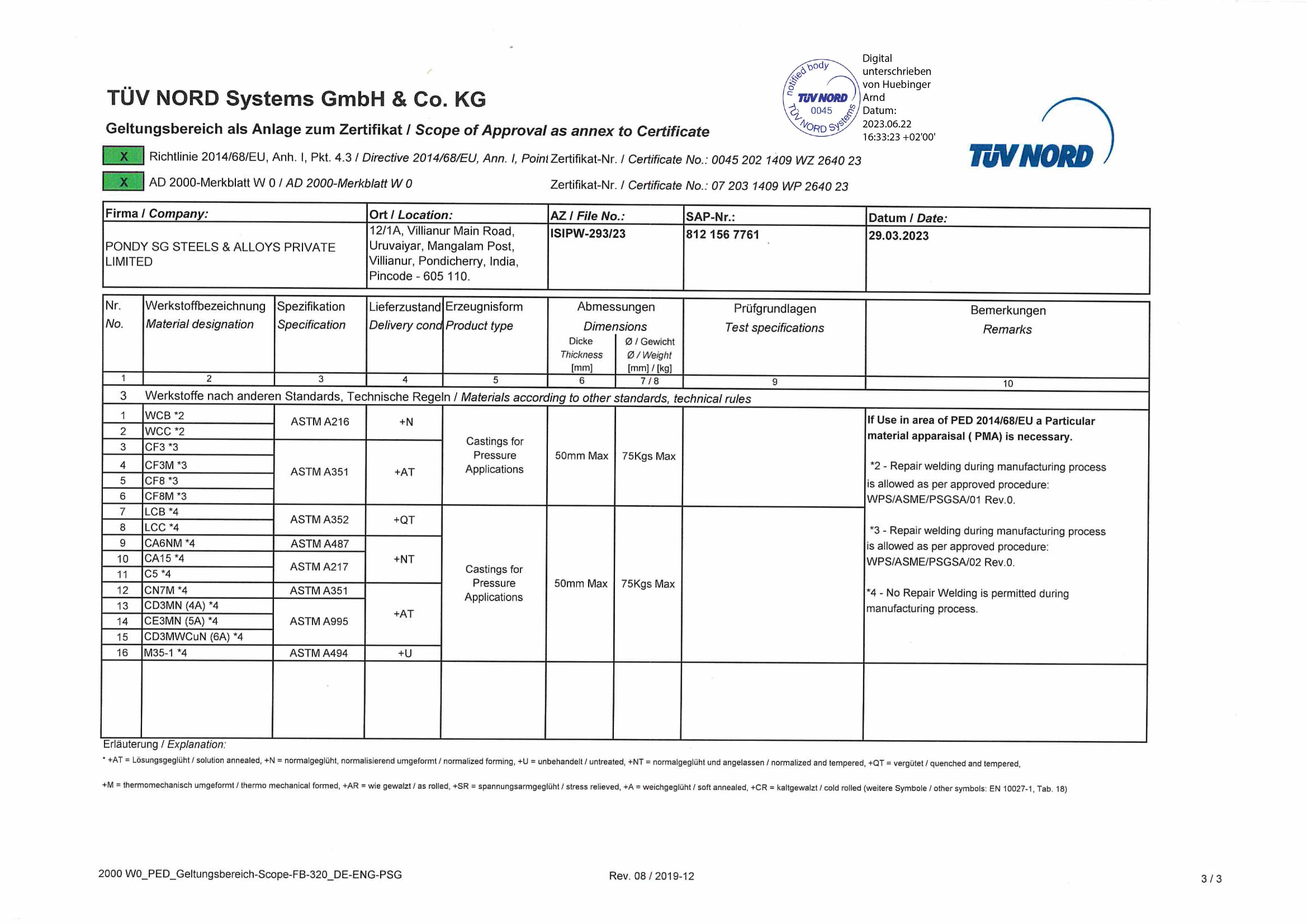

Pressure Equipment Directive 2014/68/EU (Page 3)

|

|

|

Pressure Equipment Directive 2014/68/EU

|

Material Manufacturer acc. to

AD 2000-Merkblatt W 0

|

|

|

ISO 45001 : 2018

|

ISO 14001 : 2015

|

|

|

ISO 9001 : 2015

|

|

|

INSPECTION

- Each tool is inspected prior to issue onto injection floor ensuring compliance with customer’s specifications.

- We provide first piece wax inspection as well as final inspections to ensure that all pieces are conforming

to the customer’s specifications.

- 100% Visual Inspection

- Dimensional inspection as per agreement made with customer

- Physical and chemical testing at various stages:

- Spectrographic analysis

- Slurry quality analysis

- Mechanical properties like Tensile strength, Yield Strength, Elongation percentage, Reduction area, Hardness

and Impact Testing

- Corrosion resistance Testing

- Radiographic, ultrasonic, and Magnetic Particle inspection are performed at local professional laboratories to ensure

the soundness of quality.

- Process Control of Waxes and Slurries

- 2D / 3D measuring device used for layout inspection.

|

|

INSPECTION AND TESTING FACILITY

- Ferrous &Non Ferrous Based Optical Emission Spectrometer – Brucker Q4 Tasman with Nitrogen

- Computerized Universal Testing Machine – 40T

- Optical Brinel Hardness Tester – 3000 Kgf

- Rockwell Hardness Tester

- Izod / Charpy Impact Tester – IS & BS

- Complete analytical Lab for Shell material analysis

- Surface Plate, Angle Plate and Between Center

- Measuring instruments like Digital Height Gauge, Calipers, Micro meters, etc..

- Magnetic Particle Inspection (Wet Fluorescent Machine with Enclosure) & Ultrasonic Testing Machine

- 3D Coordinate Measuring Machine

- Vision Inspection System

- Special Leak Testing Machine

- Air (25 Bar Max with Nitrogen)

- Hydro (65 Bar Max)

|